I embarked on my professional journey in 1998 as a fresh-faced graduate with the Sequoia Partnership. It was more than just a job—it was a remarkable apprenticeship that provided invaluable insights into how supply chains should work.

Supply chain consultant & technology provider

Specialist in strategic planning & operational optimisation

Clients

Selected clients

Experience

I've worked on some incredible projects over the last 25 years - here's a snippet of my experience:

Network design / supply chain strategy / footprint optimisation

Network optimisation for FTSE 100 packaging manufacturer

Supported the leadership team in the development of a £x00m investment plan to maximise return on capital and meet future growth expectations.

Supply chain strategy for UK Soft drinks manufacturer

Defined the optimal supply chain network for a leading UK soft drinks manufacturer & developed a strategic roadmap to maximize financial returns & mitigate risks during restructuring.

European distribution strategy for €10bn multinational appliance manufacturer

Determined the distribution network with the lowest cost to serve for a ‘White Goods’ manufacturer.

Optimal depot network for Bed retailer

Optimised number and location of home delivery depots for UK Bed retailer, trading off warehouse, trunking and last mile costs to define optimal network.

Manufacturing strategy for leading UK Dairy producer

Modelled optimal number & location of manufacturing facilities to balance scale benefits of large scale dairy operation with inbound and outbound distribution costs.

Fulfilment strategies for direct sales cosmetics business

Optimised number & location of Distribution Centres across Europe/Russia to migrate a rapidly expanding cosmetics business to a centralised DC network.

Online fulfilment strategy for ‘Big Four’ UK supermarket

Devised optimal online grocery fulfilment strategy for major supermarket to meet online growth ambitions.

Internal research study of Ocado’s business model

Conducted an ‘outside-in’ assessment of Ocado’s centralised approach to online grocery fulfilment, concluding that large scale automated CFCs are the most profitable fulfilment approach for online grocery orders.

Supply chain operational optimisation experience

EMEA Supply chain optimisation for ingredients business of Soft drinks brand owner

Conducted an inventory simulation including obsolescence costs to determine which product ‘kits’ could be held in stock without excessive write-off costs due to shelf life expiration.

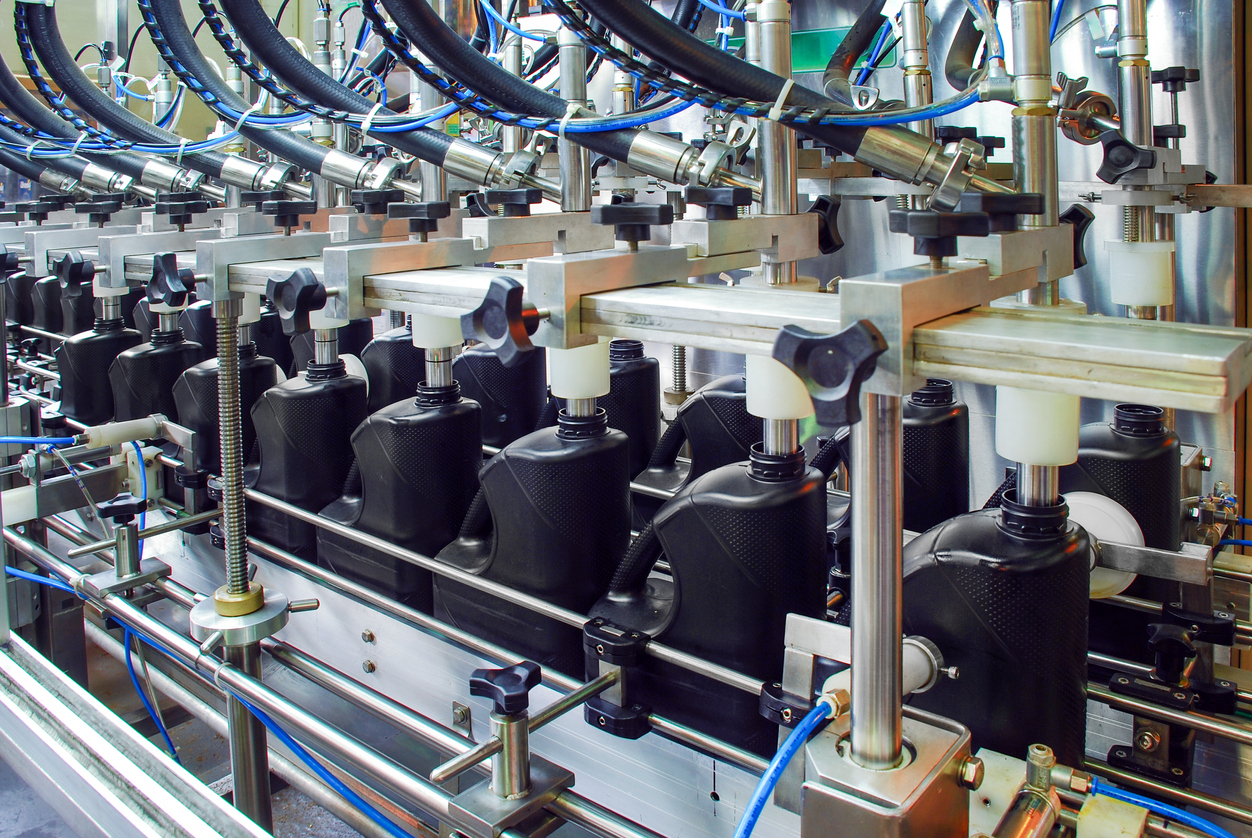

Batch size optimisation for global lubricants manufacturer

Optimised Economic Production Quantities to minimise end-to-end supply chain costs for a global lubricants business.

Production scheduling optimisation

Optimised production schedules for FMCG clients by balancing sequence changeovers with inventory and obsolescence costs.

Safety stock optimisation

Set safety stock targets for multiple clients to achieve desired service levels at SKU-location level.

Contact

Contact Us